Many people wonder where iPhones are made. Apple designs the iPhone in the United States, but the actual building happens in different countries. These countries include China, India, and a few others that support the entire process. Apple uses many partners, factories, and suppliers to produce each device. The iPhone depends on a long supply chain that joins parts from Asia, the United States, and Europe.

Where iPhones Are Assembled

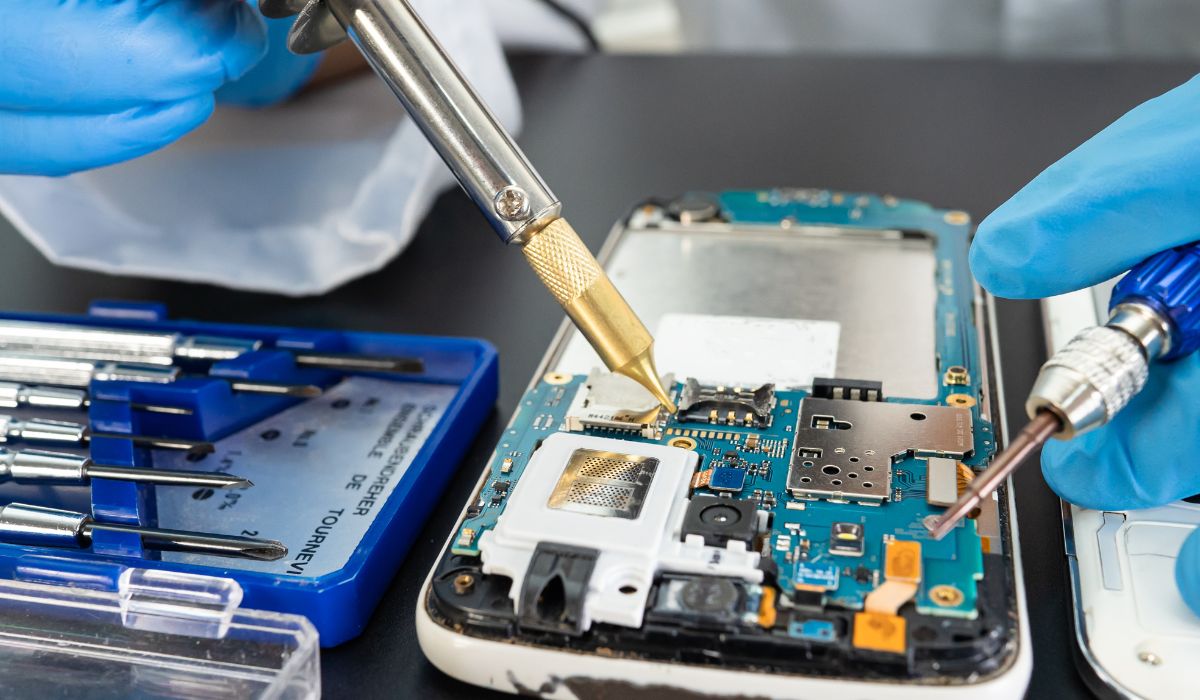

Apple works with several companies to assemble the iPhone. These plants handle the final assembly, testing, and packaging.

China

China remains the main assembly location. Foxconn runs large factories in places like Zhengzhou and Shenzhen. These factories build most iPhones because they have huge workforces and fast production lines. Pegatron also works in China. It handles part of the assembly, especially during busy launches. China stays important because it has strong supply chains and nearby suppliers for displays, batteries, and other parts.

India

India builds a growing share of iPhones. Wistron and Pegatron operate assembly plants in cities like Bengaluru and Chennai. India’s government gives incentives for electronics production, so Apple adds more lines there. These plants build newer iPhone models over time. India helps Apple spread production across different regions and reduce pressure on China.

Other Supporting Locations

Some smaller assembly support happens in Vietnam and nearby regions. These locations help with parts of the production cycle or with older models. They do not match the scale of China or India but still support the overall supply chain.

Companies That Build iPhones

Apple does not build iPhones by itself. It partners with manufacturing companies that run huge facilities.

Foxconn

Foxconn is Apple’s biggest manufacturing partner. It operates large assembly plants and handles the most complex parts of the process. Foxconn works with Apple on testing, inspection, and shipping.

Pegatron

Pegatron handles part of the iPhone assembly too. It builds many units during high demand and shares tasks with Foxconn. Pegatron works in both China and India.

Wistron

Wistron builds iPhones mainly in India. It focuses on inland production and helps Apple reach local and global markets. It works on select iPhone models and adds more lines as demand rises.

Where iPhone Parts Come From

The iPhone uses parts from companies around the world. Each piece comes from a different supplier with its own specialty.

- The A series chips come from TSMC in Taiwan

- Samsung and LG in South Korea supply displays for many models

- BOE in China makes displays for some devices

- Sony in Japan builds camera sensors

- Murata Manufacturing in Japan makes some wireless parts

- Chinese suppliers provide batteries, cables, and internal modules

- Corning in the United States supplies the glass panels

- Circuit boards and connectors come from Taiwan, Japan, and South Korea

Apple uses these suppliers because they offer strong quality and can handle large orders.

Why Apple Uses Multiple Countries

Apple spreads production across several countries so it can build millions of iPhones without delays. Each country offers different strengths. China has a complete electronics ecosystem, skilled workers, and fast production speed. India gives Apple another region to reduce risk and grow its presence. Japan, Taiwan, South Korea, and the United States help with high quality parts that the iPhone needs.

Using many places also helps Apple move production if one area faces problems. It keeps the supply chain stable and flexible.

Apple’s Global Supply Chain System

Apple designs the iPhone in California. The company sends plans and component lists to suppliers in Japan, Taiwan, South Korea, China, and the United States. These suppliers make parts like chips, cameras, modems, and displays. The parts ship to assembly plants in China and India.

At the factories, companies like Foxconn and Pegatron put the parts together. They test each phone, load software, and pack the boxes. The finished phones then move to global shipping hubs before reaching stores. This system lets Apple launch new models worldwide at the same time.

Conclusion

iPhones come from a mix of countries, not just one place. China handles most assembly, India takes a growing share, and parts come from Taiwan, Japan, South Korea, China, and the United States. Apple uses this wide network so it can build high quality phones at a massive scale. This global system keeps iPhone production steady and ready for new releases.

If you learned something new or want to share your own thoughts about iPhone manufacturing, feel free to comment and share.