Modern design and engineering are full of excitement. New tools, smarter workflows, and faster methods make it easier than ever to turn bright ideas into real-world products. But how does a rough idea become a solid design everyone agrees on?

This journey—from concept models to signed-off specs—has plenty of moving parts. Let’s explore how it’s done the modern way. Don’t worry, we’ll keep it fun and simple!

Everything Starts with an Idea

It all begins with a spark. Maybe someone says, “What if we built this?” That little inspiration sets everything in motion.

But before you can make anything, you need to get the idea out of someone’s head and into the real world.

Step 1: Concept Modeling

This step is like sketching on digital paper. Designers use 3D modeling tools like Fusion 360, SolidWorks, or Rhino to mock up ideas. These models don’t have to be perfect. They just need to show what’s possible.

- Shapes

- Movements

- Basic features

- A rough idea of scale

This helps people visualize the idea quickly. Think of it like a digital napkin doodle.

It’s way easier to show someone a 3D model than explain it with words. That’s why concept modeling saves so much time. Plus, you can build multiple versions and compare them side by side.

Bringing Ideas to Life

Step 2: Digital Prototyping

Next, engineers and designers use software to make a more detailed version of the model. This time, we get serious. We care about how it works, what materials might be used, and how parts fit together.

We also simulate things digitally. Like:

- How much weight it can carry

- What happens when it’s dropped

- How heat or pressure affects it

This helps us catch problems early before spending any money on materials.

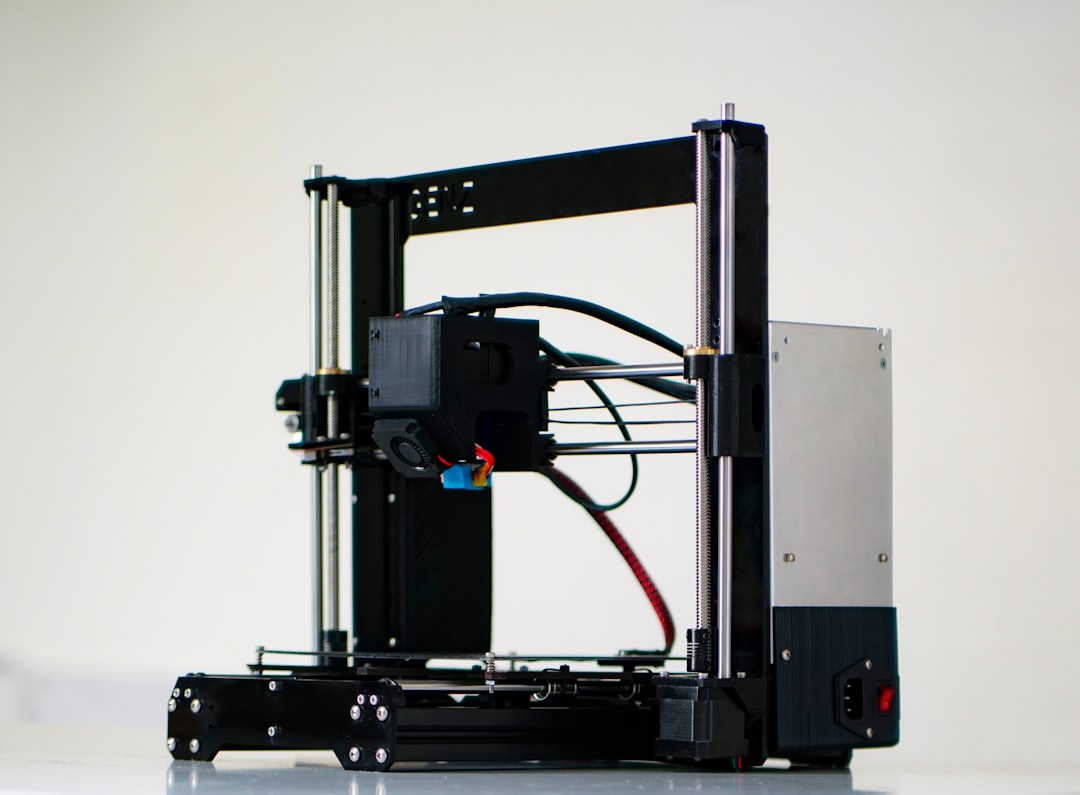

Step 3: Physical Prototyping

Once the digital model looks good, it’s time to go hands-on. Using 3D printers, CNC machines, or laser cutters, teams bring the model into the physical world for testing and feedback.

This part is really fun. A concept that started as a simple model now becomes something you can touch, hold, and test.

Image not found in postmeta

It’s also when things start to get real. You may notice issues that didn’t show up in the software. Maybe the device is too heavy. Or maybe a hinge needs to move more freely. That’s the point of a prototype!

Working Together is Key

Design isn’t done in a vacuum. Lots of people work together:

- Industrial designers

- Mechanical engineers

- Electrical engineers

- Manufacturing experts

- Marketing & product managers

Everyone needs to stay aligned. Luckily, modern project tools like Monday.com, Jira, or Notion help people stay on the same page. Updates can be shared instantly. Feedback loops are faster than ever.

Design files can even be shared through the cloud. This means teams in different parts of the world can work together as if they’re in the same room.

Refining the Design

Step 4: Verification and Testing

Once a product looks ready, it goes through serious testing. Every detail gets checked. Does it meet safety standards? Does it function in real-life scenarios?

Tests might include:

- Drop tests

- Waterproof testing

- Stress analysis

- Battery performance

- User comfort studies

This part often sends the design back for changes. And that’s okay! Good products need fine-tuning. Iterating is normal—and expected.

Step 5: Final Design Review

Once every test is passed and all feedback is addressed, it’s time for a final review. This is a meeting where everyone involved gives the final thumbs up. All design elements are reviewed piece-by-piece.

This includes:

- 3D CAD drawings

- Material lists

- Assembly instructions

- Tooling specs

- Color and finish decisions

Step 6: Signed-off Specifications

This is a big moment. When everyone agrees on the final version, the specs are signed off. That means the design is complete and ready for production. No more changes—unless something unexpected comes up later.

The signed-off specs document includes:

- All dimensions/specs

- Final material choices

- Assembly process

- Packaging requirements

- Compliance certifications

At this point, factories and manufacturers can start preparing for mass production. It’s go time!

Why This Process Works

This modern approach mixes creativity with logic. It combines beautiful design with engineering brains. And thanks to digital tools, it all happens faster and better than ever before.

Here’s what makes it awesome:

- Teams can collaborate in real time

- Prototypes are cheaper to make

- Digital models can be tested before building

- Cloud sharing speeds everything up

- Designs are more precise

And the result?

Better products. Happier users. More efficient teams.

Future of Design and Engineering

New technologies are changing the game every day. Things like artificial intelligence, generative design, and augmented reality let designers explore ideas like never before.

Imagine typing in your idea, and AI gives you five design models instantly. Or using AR glasses to place a prototype in your living room to see how it fits.

We’re entering a world where creativity and tech go hand in hand.

Wrapping It All Up

From napkin-sketch ideas to production-ready products, modern design and engineering make it all possible. Each step along the way builds on the next—from concept models to signed-off specs.

Here’s what to remember:

- Start simple, dream big

- Build fast, fix early

- Test everything

- Keep improving

- Work as a team

And above all—have fun bringing awesome ideas to life!